INDUSTRY NEWS

Injection molding machine Class C standardISO 20430

Injection molding machines are widely used in the rubber and plastic industry, and even in some metal processing industries. Its working principle is to inject thermoplastic or hot-melt materials into the injection mechanism, inject and fill the mold at high speed, and then shape it through high temperature or cooling. The rubber and plastic industry is one of the earliest industries to introduce safety standards, and the danger of its equipment is evident.

As a highly dangerous equipment, the safety protection of injection molding machines is a topic that I often bring up for educational purposes. We have previously analyzed some standard requirements for safety protection in the mold clamping area of injection molding machines, and these contents are all from the standardsISO 20430——Plastics and rubber machines – Injection moulding machines – Safety requirements,

This standard covers all aspects of safety requirements for an injection molding machine and is definitely a "treasure trove" for the safe application of injection molding machines.

ISO 20430It is a Class C standard for injection molding machines, which puts forward relevant safety requirements for the design, construction, and use of injection molding machines used in rubber processing.

Chapters 1-3

Scope, standard references, and terminology definitions

The first three chapters of the standard are the same as other standards, including scope, standard references, and terminology definitions. Users can understand which types of machines can use this standard, which other standards and specialized vocabulary and terminology are referenced in this standard, laying a foundation for reading the content of subsequent chapters.

Chapter 4

Safety requirements and protection/risk reduction methods

This chapter focuses on the basic requirements and methods of safety protection, with section 4.1 emphasizing some basic requirements such as start stop and restart function, emergency stop function, mechanical protection, grating, dual hand control, and pressure-sensitive carpet. These contents also refer to a large number of relevant Class B standards, such as emergency stop standard EN ISO 13850. From chapters 4.2-4.7, specific safety requirements for different areas of the injection molding machine are discussed, including the mold clamping area in chapter 4.2, the locking structure area in chapter 4.3, the external motion structure in chapter 4.4, the nozzle area in chapter 4.5, the injection molding area in chapter 4.6, and the discharge area in chapter 4.7. The main dangerous motion mechanisms and corresponding protection methods in each area are described, and even the performance levels of relevant safety functions or the requirements for specific protection types for injection molding machines are included. In Chapter 4, protection requirements for injuries such as heat, noise, falls/tripping/drops, pneumatic hydraulic systems, and powered protective structures are also included.

Chapter 5

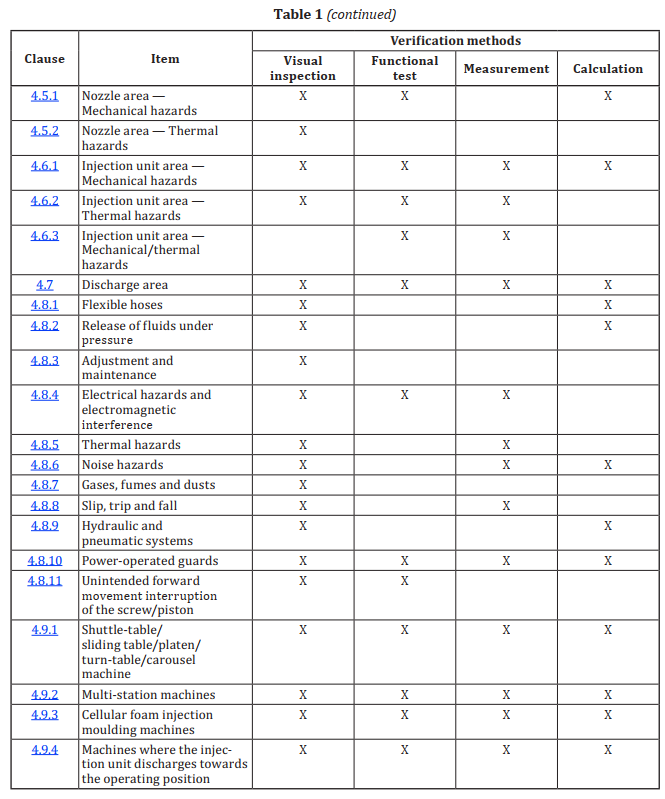

Verification methods for safety requirements

All requirements proposed in Chapter 4 are validated for effectiveness using visual inspection, functional testing, measurement, or calculation methods, summarized in one table.

Chapter 6

Use information

Chapter 6 of the standard introduces to users the requirements for providing necessary information content to relevant personnel in the use, maintenance, and cleaning of equipment, such as operation manuals and warning labels/signs.

appendix

The ISO 20430 standard includes a total of 9 appendices, including Appendix A, which provides detailed information on the significant risk points of injection molding machines and greatly assists in risk assessment. Appendices B-D respectively describe the implementation methods of ProtectiveType l-llI from a technical perspective, while the following sections include typical warning sign styles and specific requirements for noise testing.

column

NEWS

Contact Us

Zelma Industrial Technology (Hangzhou) Co., Ltd

phone:

telephone: 0571-86751613

email: sale@zelmasafe.com

address: 1st Floor, Zhenlin Science and Technology Innovation Park, Lincheng Town, Changxing County, Huzhou City, Zhejiang Province