INDUSTRY NEWS

Did you use the mechanical switch with locking function correctly?

In traditional automation fields such as automotive industry equipment, packaging equipment, printing equipment, etc., mechanical switches with locking functions are widely used. The fundamental reason is that the moving speed of the internal moving parts of the machine is fast, and the parking inertia is large. Once it causes injury to personnel, it will be quite serious. If the distance between the mobile protective equipment (safety door) and the dangerous moving parts of the machine is not far enough, the mobile protective equipment must be securely locked to prevent personnel from entering and leaving the dangerous area at will.

According to the formula S=(K x T)+C in EN ISO 13855:2010 standard, the minimum safe distance can be easily calculated.

Where K=1600 mm/s, is the speed of personnel movement, C is the additional safety distance, and T is the downtime.

The types of contacts vary greatly

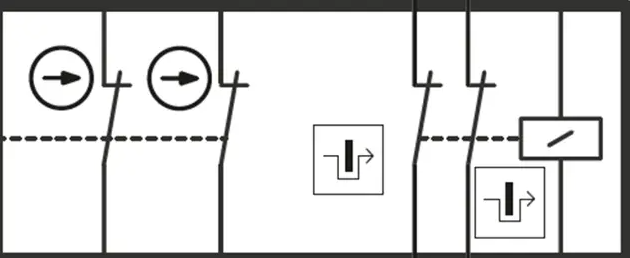

To fully utilize the locking function of a mechanical switch, it is necessary to start by understanding the contacts of the mechanical switch. Have you noticed that mechanical switches with locking functions usually provide two types of contacts. One type is the interlock status associated with the switch pin state, which will activate when the pin is inserted into the switch. Another type is the guard lock status, which is related to the switch locking state. The locking coil can only be activated when the pin is inserted into the switch, and this contact will only move at this time.

So what type of contacts are usually used when designing safety circuits?

Presumably, most of them use the guard lock status contact, because the closed and locked state of the safety door is the safety state in the vast majority of scenarios. Be careful not to use one pair of Interlock status contacts and one pair of Guard Lock status contacts, otherwise it is easy to cause asynchronous safety input circuits.

Different contact functions

So the question arises, since only the guard lock status contact is needed to determine the safety status of the mechanical switch, why do switch manufacturers still design interlock status contacts? In fact, it is to meet the application requirements of different working modes of machinery, and each type of contact has its own purpose.

Equipment usually has multiple working modes, some of which are specifically designed for equipment debugging and parameter adjustment, such as manual mode, electric mode, low-speed mode, etc. In these modes, the operating speed of the equipment is relatively slow, and the corresponding requirements for mechanical safety protection measures will also be reduced.

Taking a welding robot work unit as an example, in debugging mode, the robot is in low-speed manual operation. At this time, in order to facilitate the adjustment of the position and angle of the workpiece and fixture by the debugging personnel, and to protect the personnel, the safety door must be closed but not locked. At this time, we need to use the characteristics of the Interlock status contact to monitor whether the safety door is closed. Of course, the operating speed of the equipment in this mode also needs to be monitored for safety. In automatic mode, the device runs faster and the safety door must be closed and locked before the device can operate. At this time, we need to use the guard lock status contact to monitor the status of the safety door.

column

NEWS

Contact Us

Zelma Industrial Technology (Hangzhou) Co., Ltd

phone:

telephone: 0571-86751613

email: sale@zelmasafe.com

address: 1st Floor, Zhenlin Science and Technology Innovation Park, Lincheng Town, Changxing County, Huzhou City, Zhejiang Province