INDUSTRY NEWS

The new national standard for rubber and plastic machinery will be implemented from July 1st

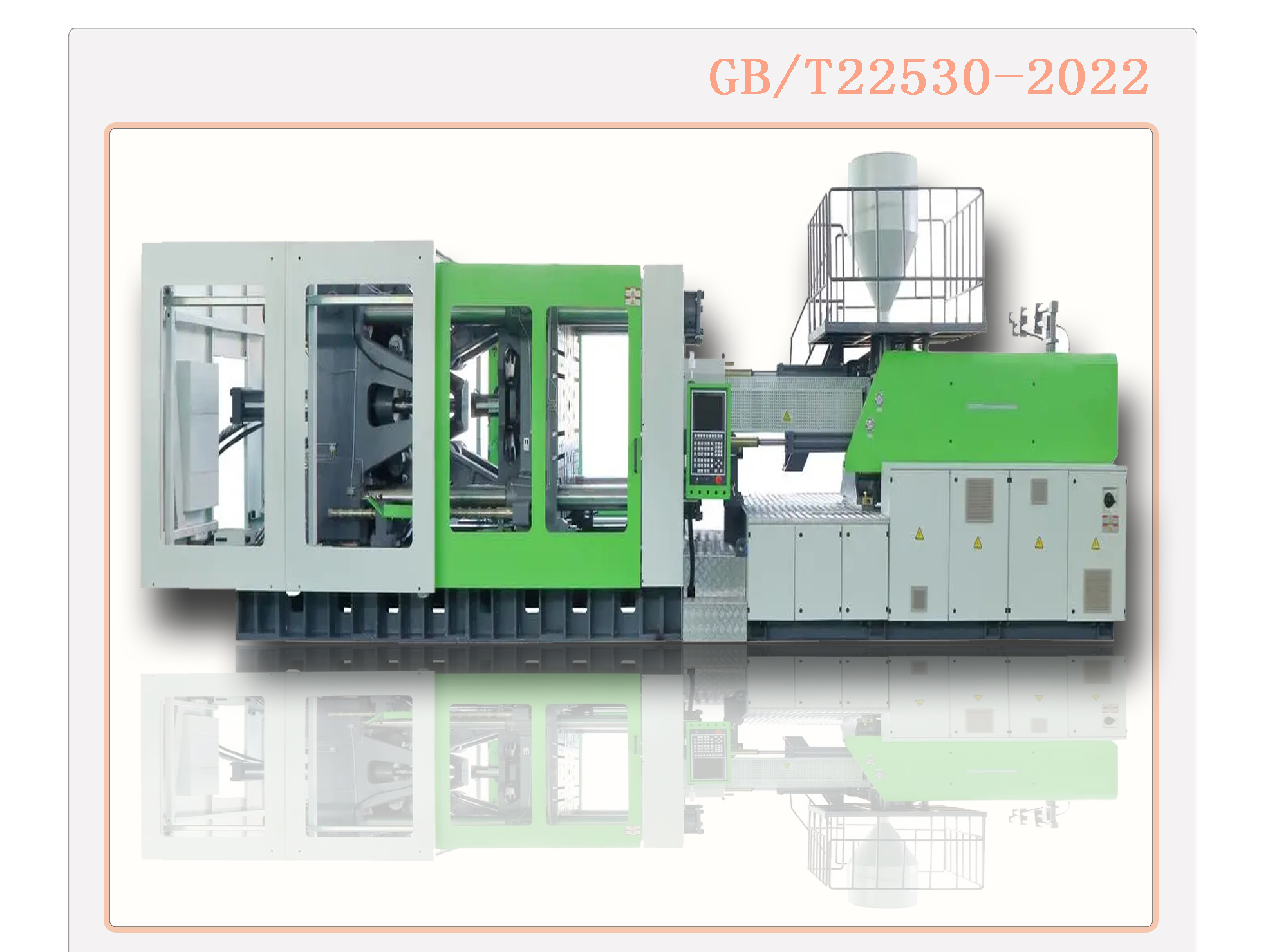

GB 22530-2008 "Safety Requirements for Rubber and Plastic Injection Molding Machines" was implemented on November 1, 2008. It is one of the earliest mandatory national standards for a specific industry in China, and has been in effect for more than ten years. In order to better align with international safety standards for injection molding machines, GB/T22530-2022 has emerged. This standard mainly adopts the technical standard of ISO 20430 (International Safety Standard for Injection Molding Machines), and is revised based on the 2008 version in conjunction with the implementation requirements of China's domestic injection molding machine industry.

EN ISO20430 is the current European and international standard and the only reference for designing CE models. GB/T 22530-2022 was released on December 31, 2022 and will be officially implemented on July 1, 2023.

2022 and 2008 versions

Main technical differences

The main technical differences between the 2022 version and the 2008 version can be summarized as follows:

2 security measures

Adopting the safety required performance level specified in GB/T16855

Adopt the provisions in the appendix of ISO 20430 standard

In the ISO 20430 standard, the List of Significant Hazards has been moved from the main body of the standard to Appendix I of the standard's data line

2 dangerous points

Unexpected movement of the template caused by the internal storage capacity of the elbow connecting rod structure

The new national standard adds a requirement for the use of power operated protective devices: if the opening movement of the power operated protective device poses a danger to the operator entering the protective device in the mold closing mechanism area, the opening movement should be interrupted, in accordance with Type I protection or PLr=c; New requirement for using light curtains for protection: Protect the grating in the mold area so that it extends to cover the entire mold closing mechanism area. When the light curtain is interrupted, these dangerous movements should be interrupted, in accordance with PLr=d.

Danger caused by accidental interruption of the forward movement of the screw/plunger

If the forward movement of the screw/plunger is accidentally interrupted, a visual and/or auditory alarm should be generated.

8 safety requirements

Consideration of hazardous downtime

Protection requirements for the risk of high pressure hose swinging, etc

Main protection ideas for injection molding machines

The danger points that injection molding machines are prone to causing harm to people are mainly concentrated in the mold clamping device area, injection nozzle area, and feeding port area, which may cause mechanical or heat source injuries to on-site personnel. In terms of protective measures, interlocking protective devices, installation of safety gratings, and installation of fixed protective devices are mainly adopted.

There are multiple options for selecting a safety controller based on the number of safety functions that need to be controlled. From safety relays that control a single safety function to modular programmable safety controls that can control multiple safety functions, there is always one that can meet the application needs of users.

column

NEWS

Contact Us

Zelma Industrial Technology (Hangzhou) Co., Ltd

phone:

telephone: 0571-86751613

email: sale@zelmasafe.com

address: 1st Floor, Zhenlin Science and Technology Innovation Park, Lincheng Town, Changxing County, Huzhou City, Zhejiang Province