INDUSTRY NEWS

Standard Interpretation | 2023 Updated Safety Standards for Autonomous Industrial Vehicles

Standard Interpretation

In addition to traditional industries such as automobiles, tobacco, and logistics warehousing, AGV has also been widely promoted and applied in various construction machinery, pharmaceuticals, chemicals, electronics, and other industries. The market size of AGV continues to grow, and many excellent AGV manufacturers and suppliers who can provide related solutions have emerged both domestically and internationally.The standard ISO 3691-4:2020, specifically designed for the safety of unmanned industrial vehicles and their systems, was officially released and implemented in 2020. It provides authoritative design guidelines for unmanned industrial vehicles from multiple aspects, including risk assessment and analysis of front-end application scenarios, hardware architecture of safety systems, software safety design, safety function testing, and on-site testing. In 2023, in order to better adapt to the requirements of technological development such as AGV safety control systems and usage scenarios, ISO 3691-4:2023 will be released and implemented.

Operation stop (added in 4.1.27 Operational stop)

When the truck is equipped with an operation stop device, the truck should remain stationary until the restart command device on the truck (such as a button pressed by a person) makes a clear action. When the truck is in a stopped operation state, it should be clearly marked. After the truck stops, the stop status should be monitored by the safety control device. When the safety related monitoring stop function fails, the stop category should be 0 (as specified in IEC 60204-1:2016+AMD1:2021, 9.2.2). The relevant safety functions of vehicle stop monitoring should meet the safety performance level of PLc as shown in the following figure.

Emergency stop (4.8.1 Emergency stop modification)

In the new version of the standard, the following description has been added to the emergency stop function:

1.In order to prevent the emergency stop function from triggering and cutting off all power sources, which may cause additional hazards, it is necessary to maintain the power source of some vehicle actuators but not be able to perform actions (such as load power fixing devices, etc.).

2. The emergency stop device should be installed on both sides of the vehicle, and the maximum distance between the two should not exceed 1200 mm.

Entry and exit methods and passenger protection (new)

The new version of the standard adds the following requirements for the entry and exit methods and passenger protection of unmanned industrial vehicles:

① 4.1.17 Seating

The requirements should refer to the relevant content of IOS 3691-1:2011, ISO 3691-2:2023, and ISO 3691-6:2021.

② 4.1.18 Entry and exit methods

The requirements should refer to the relevant content of IOS 3691-1:2011, ISO 3691-2:2023, and ISO 3691-6:2021.

③ 4.1.21 Channels and emergency exits

Vehicles should be designed or installed with devices to prevent personnel from being trapped inside the vehicle. The carriage must have passages and emergency exits that comply with ISO 2867:2011 standards. The emergency exit can be a window that allows escape from a different direction than the normal exit.

④ 4.1.22 Driving position

The requirements should refer to the relevant content of IOS 3691-1:2011, ISO 3691-2:2023, and ISO 3691-6:2021.

⑤ 4.1.24 Protective Structure

The requirements should refer to the relevant content of IOS 3691-1:2011, ISO 3691-2:2023, and ISO 3691-6:2021. Protective structures should be provided in two situations: autonomous driving mode with occupants and manual mode with operator seats.

Restricted area (speed limit removed)

In a restricted area where personnel detection systems and escape spaces cannot be provided, the new standard has removed the speed limit of 1.2m/s for unmanned industrial vehicles.

Accumulation of static electricity (added in 4.1.23 Electrostatic charges)

The design of autonomous vehicles should be able to prevent the accumulation of static electricity or provide devices for dispersing static electricity (such as belts, woven belts, chains, conductive tires, etc.).

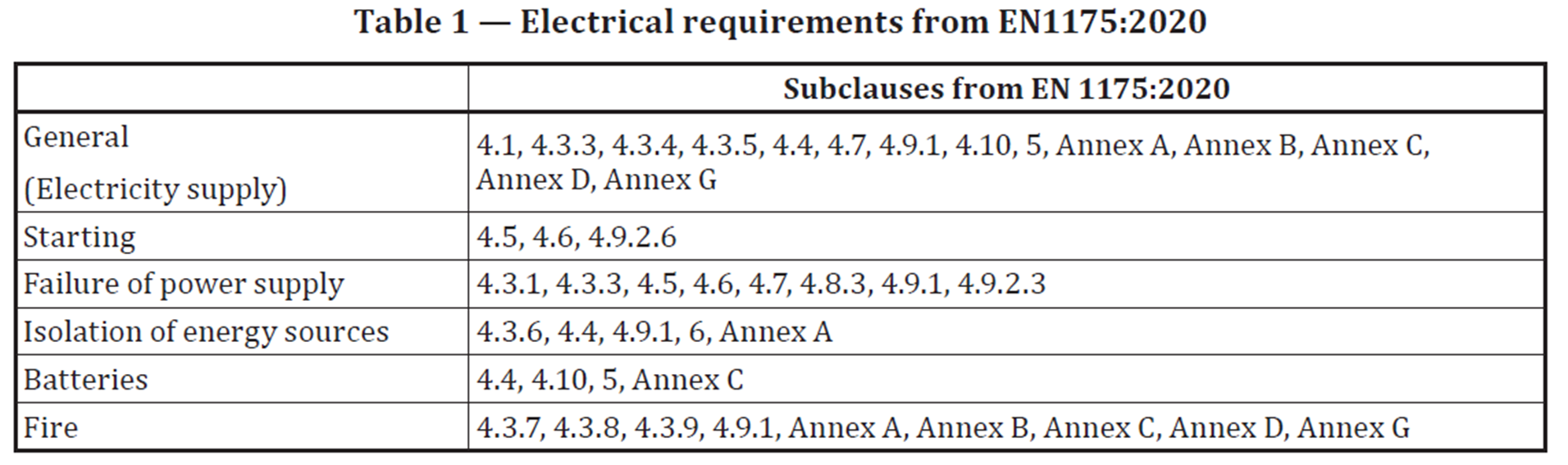

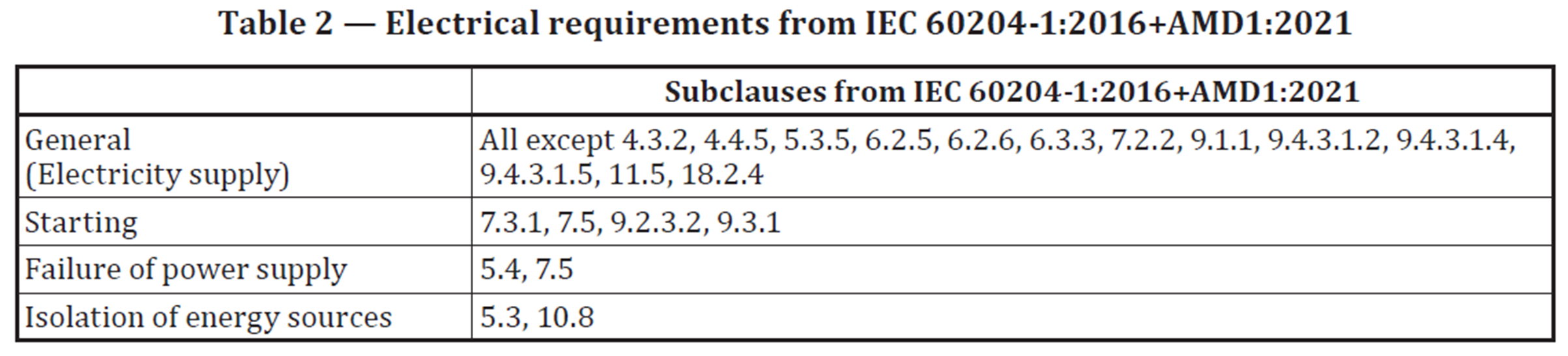

Electrical requirements (4.1.3 Electrical requirements modified)

Better link and clarify electrical requirements.

Among them, the latest version of EN 1175:2020 "Safety Electrical/Electronic Requirements for Industrial Vehicles" has been taken into account.

column

NEWS

Contact Us

Zelma Industrial Technology (Hangzhou) Co., Ltd

phone:

telephone: 0571-86751613

email: sale@zelmasafe.com

address: 1st Floor, Zhenlin Science and Technology Innovation Park, Lincheng Town, Changxing County, Huzhou City, Zhejiang Province