MECHANICAL SAFETY SERVICES

Safety Verification

Have the confirmed mechanical safety protection measures been correctly implemented? Does the design and implementation of your machinery's safety related control system comply with your safety requirements and specifications? International standards such as ISO 13849, IEC 62061, and IEC 61508 require verification of safety systems, and this verification is not limited by design functionality. Verification is the key to confirming the safety of your machinery.

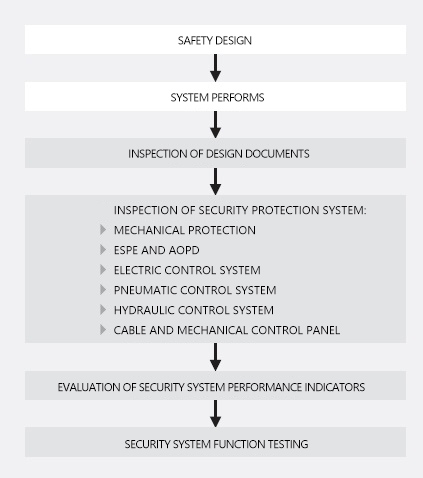

Adopt a structured approach to inspect critical safety components of equipment and machinery.

Evaluate the implemented designs in response to safety requirements

Check the installation and wiring configuration of the sensing device and triggering device

Simulate fault conditions and conduct functional testing

Check the protective devices and photoelectric protection devices

When integrating a single machine in a factory or optimizing the safety of existing machines, the time left for you is usually limited. Zelma can help you safely implement security measures within the required time frame.

Quickly implement security measures

The implementation of security measures plays an important role in mechanical networking or retrofitting existing equipment. However, in practice, the time for implementing these measures is usually very limited. It is crucial to implement targeted measures quickly.

The direct way to make machinery safer

In automation and security projects, security systems and their implementation should not be the cost determining factor, which is important for you. As part of the system implementation, we will be responsible for implementing your security measures.

When implementing security functions, our experienced project managers keep the restrictions on the production process within an absolutely small range. In order to plan project development and installation of mechanical, electrical, and hydraulic components, we will consider existing equipment conditions to minimize downtime as much as possible.

Zelma's system implementation includes the following stages:

Project planning and management

Select and procure necessary components, such as actuators, sensors, and control devices

Design and assemble necessary mechanical structures

Design and test necessary electrical cabinets

Install electrical and control systems

Programming control and visualization systems

System debugging

Select suppliers and contractors

Training for machine operators and maintenance personnel

Provide documentation to track the development process and follow structured workflows

NEWS

Contact Us

Zelma Industrial Technology (Hangzhou) Co., Ltd

phone:

telephone: 0571-86751613

email: sale@zelmasafe.com

address: 1st Floor, Zhenlin Science and Technology Innovation Park, Lincheng Town, Changxing County, Huzhou City, Zhejiang Province